The main problems with phenolic foams reported in the 1980 s were their relatively low compressive and flexural strength and their friability or tendency to crumble.

Phenolic foam roofing insulation problems.

Briefly a phenolic foam remediation project demands these steps.

If you have phenolic insulation in your roof you should be aware that it can cause severe.

In a short amount of time this sulphonic acid corrodes both standard painted deck as well as galvanized deck.

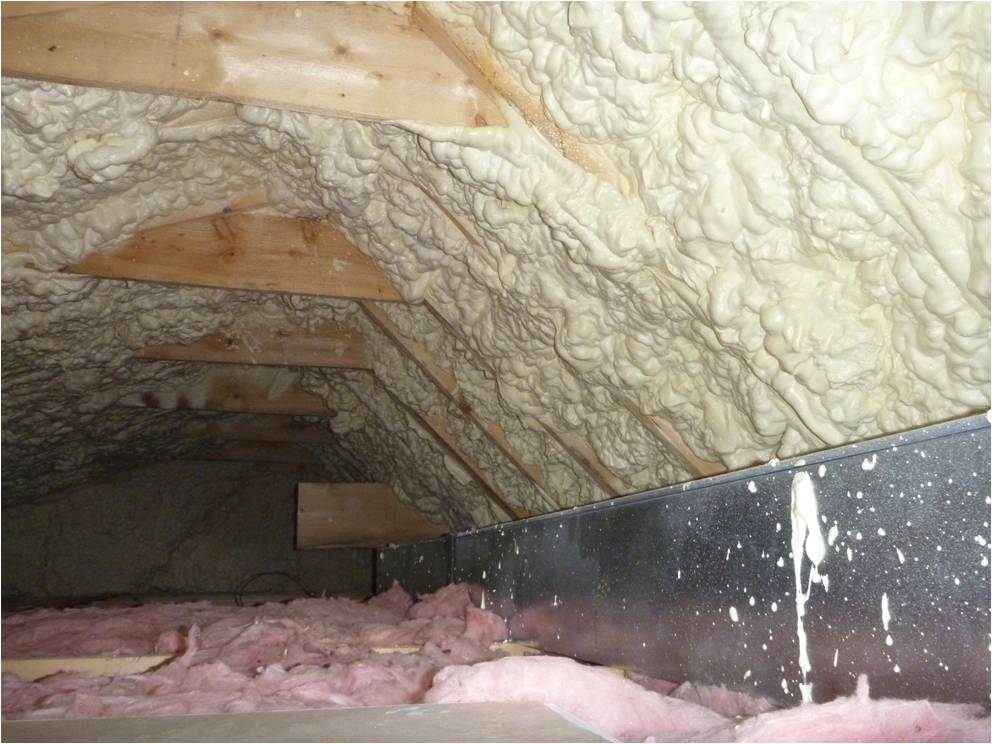

Spray foam roofing problems and myths answered.

Continual improvements in the formulations of phenolic foam board insulation products may overcome these drawbacks.

Only a day s worth of work should be undertaken to avoid leaving the building vulnerable to the elements.

Hundreds of millions of square feet of phenolic foam produced in oak creek were installed on structures nationwide between 1981 and 1992 according to the companies.

Beazer pfri has been the subject of a putative class action lawsuit in which the plaintiffs allege that beazer pfri causes severe corrosion to metal roof decks and other damage to roofing systems.

The risks of phenolic foam insulation shrinkage.

Pinhole or pitting corrosion problems are common with copper pipes steel water pipes and stainless steel steam pipes when insulated with phenolic foam and the pipework gets wet.

In the 1980s and sold by beazer east and johns manville but serious corrosion problems resulted in legal action and both companies ceased production in 1992.

Remove all corrosion from deck by wire brushing.

When it was installed over a lightly primed painted metal deck any water in the roof system from above moisture from operations or humidity within the building activated chemicals in the phenolic foam which caused corrosion of the metal deck.

Because a number of commercial roofing companies have installed this roof system poorly or incorrectly this misnomer is one of the greater misperceptions to emerge in the commercial roofing industry.

It alleges that the phenolic foam roof insulation applied to two east coast buildings corroded the underlying steel deck and other metal components.

Removal of existing roofing materials and insulation down to the deck.

Phenolic insulation exposed to humidity or direct moisture such as roof leaking creates sulphonic acid.

Phenolic foam insulation is known to shrink after curing placement in the walls of your home or between.

The phenolic foam roof insulation turned out to have a critical flaw.